(click on photos to enlarge image)

AUGUST WELLNER & SONS, SILVER PLATING FOUNDRY IN AUE,

SAXONY

Introduction

The information about the August Wellner company in the

English (or American) literature is extremely scarce. The

internet sites ebay.com and ebay.co.uk, while selling Wellner

pieces, advertise this firm mostly as a supplier of silver

pieces for the "German 3rd Reich High Command" or "Hitler and

the Nazi Party". Very often the usual silver-plated Wellner

pieces made for the transatlantic passengers in the beginning of

XXth century are passed off as being issued for Hitler troops.

For example, the wide-spread logo HAL which means

Holland-America Line (by other sources, Hamburg-America Line or

Hamburg-Amerika Linie) is transformed by careless sellers to LAH

(Leibstandarte Adolf Hitler). It is needless to say that the

prices for such "historical" silver-plated items are in the

order of hundreds of dollars. Therefore, one of my primary goals

while writing this paper (and the accompanying one on Wellner

marks) was to give a more correct picture of this nearly

forgotten company.

Closing the introduction, I wish to remind readers of a few

important facts regarding the 160 year long history of the

Wellner company. The factory August Wellner & Sons was always

one of Germany's largest manufacturers of cutlery and hotel

tableware dating back to imperial times. Its products were

world-renowned for their high quality and beautiful styles. In

1911, the factory August Wellner & Sons became one of the

greatest silver-plating enterprises in the world, yearly

producing 3 million dozen of cutlery [1]. In 1913 the company

employed 5000 people [2]. The firm supplied many European luxury

hotels, among them Grand Hotel in

Lido in Venice, Baur au Lac in Zurich, Hotel Kempinski in Berlin,

Kurhaus in Davos, Maloja Palace Hotel in St. Moritz, to name but

a few. The great passenger liners, such as Titanic (UK),

Imperator (Germany), Saturnia and Vulcania (Italy), used Wellner

cutlery in their restaurants.

Alpacca alloy and silver plating

The famous August Wellner metal goods factory was founded by

August Wellner's father, Christian Gottlieb Wellner, in the small town

of Aue (Saxony, Germany), embedded in the wooded hills of the

Erzgebirge (which translates in English to Ore Mountains). This

part of Germany was traditionally involved in the smelting

business. As early as 1663 a tin foundry was established in Aue

(which means "flood plain"), which was in operation until 1803.

Fifty years after closure the factory buildings were used as a

starting point for the August Wellner metal goods factory.

However, before this happened, an important invention was made

in the neighbouring city of Schneeberg ("snow mountain"). In

1823, the German chemist Dr. Ernst August Geitner (1783-1852)

[3] developed a new alloy, very similar in its appearance to

silver, but significantly cheaper. Therefore, he called this

alloy "Argentan". It consisted of 20% nickel, 55% copper and 25%

zinc. Later, in 1829, Dr. Geitner established his Argentan

foundry in the Aue suburb of Auerhammer.

|

Portrait of Dr. Ernst August Geitner, inventor of Neusilber [4].

|

The new silver-imitating alloy soon became very popular. The

foundry Henninger Brothers (Gebruder Henninger) in Berlin

proposed a similar alloy (5-30% nickel, 45-70% copper and 8-45%

zinc with trace amounts of lead, tin and iron) in 1854 [3],

which was called "Neusilber". Later both Argentan and Neusilber

were used in Germany and Austria-Hungary under the trade name of

Alpacca which corresponds to the name of the animal pasturing on

South American Andes of Chile, Bolivia and Peru, Alpaca in

English.

As this new alloy was quite similar in appearance to genuine

silver, some people got the idea of using it as a base metal for

future plating with a thin silver layer. Such silver-plating

could be done by different methods but the high-voltage

electrical deposition enjoyed wide application. By doing this

two goals were immediately reached: 1) the cost of the final

silver-plated product was decreased by 5-7 times due to the much

lower amount of silver used for plating; 2) the appearance of

the objects was as perfect as a silver one and did not change

significantly with the wearing away of the silver layer. As a

result, numerous silver-plating enterprises were founded in the

mid XIX century, among them the famous Hermann Krupp & Alexander

von Schoeller, Berndorf, Austria-Hungary (1843), Charles

Christofle, Paris, France (1844), Axel Gabriel Dufva, Stockholm,

Sweden (1847), Christian Gottlieb Wellner, Aue, Saxony (1854).

Carl August Wellner

The founder of the Aue metal factory Christian Gottlieb

Wellner (1795-1857) [5] started his career very early at the age

of 15. First he worked as a miner, then as a forester, later he

joined Geitner's Argentanfabrik. He had six children, amongst

them two brothers, the elder one, Carl August (1824-1909, later

another transcription of his name, Karl August, was also used)

[6] and the younger one, Christian Gottlieb junior, who was born

in 1831. Both became silver plate manufacturers and settled in

Aue, but Carl was much more succesful. He attended school in Aue,

did an apprenticeship as a carpenter and acquired his master

degree in 1854. After the death of his father he inherited a

part of Argentanfabrik in Auerhammer. In 1858 Carl August

returned back home after three years of wandering (a kind of

pilgrimage mixed with probation) and took this foundry under his

management. In 1862, he visited the Berlin Neusilberfabrik of

Henninger brothers to acquire specialised knowledge about the

further processing of Argentan into sheets and finished products.

On 13th July 1851 Karl August married Karoline Schott from

Bärenwalde ("bear forests"). In the following years he fathered

five sons: Ernst Emil (1853-1911), Albin Ernst (1858-1925), Gustav Emil (1860-1929), Hermann (1862-1890), Richard Paul (1866-1925) and a daughter Ida Marie (1864-1943).

Carl August continuously struggled for the expansion and

technical innovation of his business. The starting point of

Wellner's world class machinery was the acquisition of a spoon

roller mill and a new spindle press. In 1870 he acquired the

building of "alte Langmühle" (old long mill) in Aue for 9000

Talers (German currency at that time), in order to exploit

hydro-power (water power) for more energy independence [7].

However, all his plans were difficult to put into the practice

due to dry summers and the war between Germany and France, which

caused an increase in metal prices. His hardest stroke of fate

was in 1872 when he lost his beloved wife Karoline due to a

tragic accident at the plant. Karoline was actively involved in

the shaping of spoons, got caught in one of the cog wheels of

the press gear box and was killed. After that, in 1874, Carl

sold this ill-fated Langmühle to the weaver Geissler for 18000

Talers [7]. He however stayed as a tenant in Langmühle for

another ten years before he acquired a meadow of 5700 square meters

below the Schmelzhütte (smelter),

which became the central site of his enormous (by that time)

factory. Plans for the new factory building included a new

roller mill and wire drawing plants as well as high power steam

engines [7].

Carl August Wellner was a very talented craftsman and inventor

and was always very supportive of other smaller Aue companies

such as the machine factory Schorler & Steubler, the tin

manufacture Karl Fischer, the fabric factory Simon Brothers, to

name a few. They worked under his auspices and Wellner

encouraged them to found independent business solutions and

become self-employed. August Wellner liked to work as a

cabinetmaker, especially for the production of so-called Vienna

chairs, hence he kept a joint venture with chair manufacturer

Christian Becher [7]. Later the two partners separated, because

Wellner was concerned with chair quality and Becher with their

quantity. After his wife's tragic death, August Wellner passed

on his chair and

furniture manufacture to his favourite son Ernst. Ernst's

company was officially independent but unofficially was always

supported by the metal works of his father. August Wellner was

very committed to helping the chair manufacture which partly

used the new site (newly acquired meadow) for this purpose. He

built a new plant for wood machining with three reciprocating

saws. In contrast the new silver ware manufacture was first

housed in a somewhat unimpressive building complex with only a

few hand presses and metal sanding-polishing machines [7].

If August Wellner had put all his efforts from the very

beginning into "Edelwarenfabrikation" (silver metal works),

rather than into supporting other activities, e.g. wood

machining, he would have become a famous entrepreneur much

earlier. Despite the continuous advancements of his company

since 1860 the scale of the company's turnover remained

relatively modest due to the lack of trading skills in business.

The reason for this was the complete neglect of the commercial

side of its operation. Indeed, although August Wellner was a

top-class craftsman, he was a rather poor businessman. For

example, he was strongly against employing accountants; as a

result this part of work dealing with

business/trading/accounting had to be done on the side by his

fourth son Hermann and his daughter Marie (during their

leisure-time!).

In 1887 the "full-time" tradesman Karl Krause from Leipzig was

hired as a sole distributor of the entire new-silver production

[7]. Formally a branch of August Wellner's company was founded

in Leipzig, which was headed by Krause. In practice, however,

this was a "one-sided treaty". Wellner delivered all his

products to Krause at fixed prices and Krause sold the products

at arbitrary prices. In retrospect, notwithstanding

the fact that Krause was a serious and distinguished

businessman, highly rated by Wellner, he should have paid higher

prices to Wellner to help him to expand his silver production.

Certainly, both sides could have benefited from it. When Krause

joined the company there were 18 employees and 35 children (school

pupils) working in the factory, when Krause died (in 1892),

there were 50 full-time employees [7]. In 1891 the annual wages

were 50,000 Marks (German currency of that time), the turnover

that year was 180,000 Marks [7].

|

|

Photograph of August Wellner, taken

from [4].

Under the photograph there is an inscription:

Karl August Wellner, pioneer of German cutlery

industry,

2 May 1824 - 25 May 1909.

|

In 1892, Karl August Wellner formally transferred the

management of his factory to two sons: Albin and

Paul, and daughter Marie, but still retained his personal

guidance until 1895 [7]. Two years before his death in 1909, he

was able to see his life achievement, his famous plant, being

finished.

|

|

August Wellner's gravestone in Aue

cemetery. Below the portrait of August Wellner

there is a

contour of a new factory building built in

1897-1907 (see below).

The photograph was taken by

Angela Monika Arnold in 2009 [8].

|

The achievements of Karl August Wellner are well known and

widely recognised. In compiling this paper, I wanted to pay

tribute to his much less known successor, Paul Gaedt, who played

a major role in the succesful continuation of the factory

business after the retirement of August Wellner in 1895.

Paul Gaedt

The family of Peter Paul Gaedt (1867-1948) [9] originated

from the Rostock area. His grandfather and father kept a tannery

in Gerberbruch. Because of the decline in the tannery business,

their son/grandson graduated after completing a training school

for plumbers. Looking for a job after two years of wandering,

Paul Gaedt came to Aue on 2 January 1890. Here he found work in

the sheet metal and metal goods factory Max Boehme, and later

became acquainted with two sons of Carl August Wellner, Ernst

and Hermann. That led to a relationship with Carl August's

daughter Ida Marie. Soon Paul Gaedt gave up his position at the

Max Boehme and began working with Wellner.

After his engagement to Ida Marie in 1890, on behalf of his

future father-in-law, Gaedt continued his pilgrimage to acquire

additional skills, especially belt-making. He came via Carlsbad

and Prague to Vienna. A relative of Paul Gaedt gave him a job in

the famous Artur Krupp factory in Berndorf [9]. He became

acquainted with the modern cutlery manufacturing process and to

improve these skills went further to the Christofle foundry in

Paris. However, later that year Karl August Wellner called him

back to Aue, because his son Hermann had died of blood poisoning.

Hermann Wellner fulfilled accounting and administrative

functions in the Wellner company and these were now transferred

to Gaedt. In 1891 Paul married Ida Marie Wellner and became

co-owner of the thriving cutlery factory and later the president

of the August Wellner & Sons company.

At the beginning of his career, Paul Gaedt efficiently

eliminated the economic difficulties which had threatened the

company through the existing exclusive contract with Karl Krause.

On 20th October 1892, Gaedt erased the previous name of the firm

August Wellner from the Register and instead registered Saxon

Metal Goods Factory August Wellner & Sons as a start-up company

[7]. Thus this "one-sided" contract became invalid, which was

extremely important for the survival and further economic

development of the company. Paul Gaedt received the full trading

rights for the company Wellner. Under Gaedt's leadership, a new

factory building was created (in 1897-1907 [7,8]), necessary

machinery and implements were purchased and product distribution

was extended throughout Europe. In 1913 Gaedt accomplished the

conversion of the former private company into a stock

corporation Sächsische Metallwarenfabrik August Wellner Söhne

Aktiengesellschaft (AG), or Saxon Metal Goods Factory August

Wellner and Sons joint-stock company.

|

|

Building of August Wellner & Sons'

Saxony Metal Goods Factory in Aue,

erected

in 1897-1907. Note the elephant bas-relief

on the pediment of a corner building.

The photograph was taken by Angela Monika Arnold in

2008 [8].

|

|

|

The cupola of the building of

Saxony Metal Goods Factory August Wellner & Sons in

Aue.

The photograph was taken by Angela Monika Arnold in

2008 [8].

|

|

|

The entrance to the building of

Saxony Metal Goods Factory August Wellner & Sons in Aue.

Under the

left bas-relief there is a stone with a

date 1907, which probably relates to the

accomplishment of the

building

This is a fragment of the photograph which was taken

by Angela Monika Arnold in 2008 [8].

|

|

|

The marvellous Art Nouveau 1000 Mark

share of Saxon Metal Goods Factory August Wellner

and Sons,

printed

by the renowned E.A. Brockhaus Publishing House in

Leipzig, Germany. This share is dated 23rd

September

1913. Note two cornucopias (horns of plenty) with cutlery

and hollowware coming out.

In the oval,

the sketch of a new factory building in

Aue is placed. Below, there are three portraits of August Wellner

and

his sons Albin and Paul.

Above the oval, there is a portrait of Paul Gaedt.

|

The 60th Gaedt birthday in 1927 was celebrated with a big

party. In subsequent years of the world economic crisis Gaedt

organised a number of loans from large banks to ensure the

survival of the factory. In 1936 Paul Gaedt transferred the

management of the company to the former chairman Francis Cramer.

Gaedt retired and soon had to accept that the cutlery factory

Wellner partially produced war products and therefore was

expropriated by the end of the Second World War. His house in

Aue and that of his daughter were seized by the Soviet occupying

power. After that this highly-respectable retired boss was

forced to settle in his garden shed, but later moved to the

house of his daughter&s family in Glauchau where he died in

1948. He is buried in the family tomb in Glauchau-Reinhold grove.

After the end of World War II the Aue factory continued to

operate and soon became the largest cutlery producer in GDR,

employing over a thousand people; however, the name of the

company was changed again in 1958 to VEB Auer Besteckund

Silberwarenwerke (ABS) or in English "Aue Cutlery and Silver

Items Company". The company held this name until 1992 [10], when

it was changed back to Wellner Bestecke und Silberwaren, GmbH,

Aue (Wellner Cutlery and Silver Items, Ltd., Aue). After the

reunification of Germany (in 1989) the company passed through a

number of mergers and bankruptcy. The silver-plating factory in

Aue was closed in 2001, but manufacturing of cutlery under the

Wellner mark is still continuing in neighbouring Schneeberg. The

new name of the company is Wellner/ABS GmbH (Wellner/ABS Ltd.) [11].

Silver content standards used for cutlery

August Wellner & Sons pioneered also in the standardisation

of silver content in their silver-plated cutlery products. Before 1911

the following standards for silver content

were introduced:

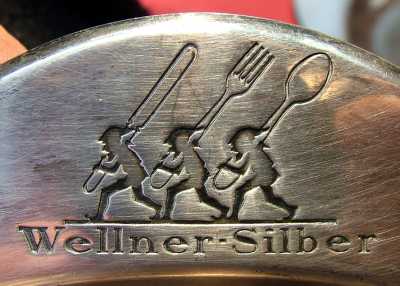

1) WS grade or "Wellner Silber" (Wellner Silver), the highest

quality standard, which corresponds to 100 grams of silver being

used for the plating of two dozen pieces of cutlery;

2) ES grade or "Extra Stark versilbert" (Extra Strong silvering), which corresponds to

90 grams of silver being used for the plating of two dozen

pieces of cutlery;

3) I grade (First Grade), which corresponds to 60 grams of

silver being used for the plating of two dozen pieces of cutlery;

4) II grade (Second Grade), which corresponds to 48 grams of

silver being used for the plating of two dozen pieces of cutlery;

5) Pure Alpacca, which means that no silver was used for plating.

The most expensive was of course "Wellner Silver", which was

advertised by the factory as "a perfect surrogate for genuine

silver" with a 20 year guarantee [2]. According to [1], in 1910

one dozen pieces of silver-plated cutlery made by August Wellner

& Sons and covered with WS grade plating cost 32 marks. At the

same time the same amount of cutlery plated with ES grade

coating cost 30 marks, with I grade coating 26 marks, with II

grade coating 22.80 marks and the dozen pieces of cutlery made

of pure Alpacca (uncoated) cost only 11 marks.

Heraldry of the August Wellner & Sons factory

In the interim between the XIXth and XXth centuries it was

common practice for jewellery companies to introduce some

specific elements into the firm mark and use these elements in

the catalogues and for advertisements. For example,

Austria-Hungarian foundry Artur Krupp Berndorf used in its marks

the profile of the bear, the French company Widow Charles

Halphen - the image of the goat head, while German Württemberg

Metal Factory applied the profile of the running ostrich. August

Wellner & Sons firm used a number of such elements in their

heraldry, first of all the image of the elephant embodying the

strength of silver coating and the dice image symbolizing luck

and diversity. The first element was used mainly on cutlery

while the second mainly on table hollow ware products. Another

Wellner logo, the combination of the three letters "AWS" (August

Wellner Sohne which means August Wellner & Sons) was introduced

before 1914. Later, this logo was used together with a contour

of a saucepan placed behind. Finally, in the twenties, the image

of three elves bearing a knife, fork and spoon was introduced.

Now, I will give examples of the use of these elements by the

August Wellner & Sons company.

Heraldry in architecture

In 1907 the new factory building in Aue was completed. The

upper part of the corner (see photo above) is decorated with a

bas-relief of the elephant stepping on a dice. The entrance (see

photo above) possesses two bas-reliefs of man figures ("atlantes")

carrying the "Wellner dice" (left figure) or the elephant (right

figure). It should be noted that the dice is always fixed in one

and the same position: one pip is visible from the top, two pips

and four pips are visible from the side view, finally six pips

are visible from the bottom.

|

|

The bas-relief of the elephant

stepping on the dice

on the pediment

of corner building of Aue Metal

Goods Factory. The fragment

of the photograph taken by Angela

Monika Arnold in 2008 [8].

|

|

|

The bas-reliefs of the dice and

the elephant on the entrance of Aue Metal Goods

Factory.

The fragments of the photographs taken by Angela

Monika Arnold in 2008 [8].

|

Heraldry in silver-plated advertisement items

Recently, at an ebay auction, a gorgeous silver-plated

elephant figurine treading on the dice was offered. On the

pedestal of this figurine, the following four inscriptions could

be seen: "Sächs. Metallwaren Fabrik", "August Wellner Söhne", "Aue

i./Sa.", and "Glückauf 1912". The first three letterings mean

Saxon Metal Factory August Wellner and Sons, Aue in Saxony. The

forth lettering is the typical greeting for German miners,

finishing work and leaving the mine, which means "Happy reaching

the upper level!" or "Happy finishing the work!" If we remember

that Aue is situated in the Ore Mountains, then it is natural to

presume that this figurine was probably used to commemorate the

achievements of the Wellner foundry in 1912. A similar elephant

in the other ebay auction bears two letterings: "Wellner Silber"

(Wellner Silver) and "Weltmarke Wellner ist unübertrefflich"

(The worldrenowned Wellner brand is unbeatable!).

|

|

Silver-plated Wellner elephant

figurines.

|

In my collection, there is a silver-plated knife for paper

cutting and/or envelope opening. Photographs of this knife

handle are given below. The inscriptions on this handle

correspond well to the inscriptions on the first elephant

figurine discussed above. This makes it possible to refer this

knife to same period, i.e. 1910-1915.

|

|

|

Inscriptions on the handle of

Wellner silver-plated paper knife.

|

Finally, some fragments of silver-plated ash-trays produced

by Wellner and used for the purpose of advertising are given

below. You can see the logo with three elves, the AWS logo and

the elephant silhouette.

Heraldry in advertising

The Wellner company also actively used its symbols in ads.

At my disposal there is an advertisement of Wellner products,

published in a local Saxony magazine in March 1925 [4].

Interestingly, here all four characteristic elements of Wellner

heraldry are used simultaneously.

|

|

Public advertisment of August Wellner

& Sons company published in 1925.

The inscription in the upper two lines means "Wellner

silver is the best surrogate for

genuine silver!" The inscription in the next three

lines means "Cutlery, Hotel- and

Tableware with unbeatable design and quality

preferable everywhere".

Below, the number of working force, 4000 workers, is

mentioned.

|

Heraldry in the marks of silver-plated items

Of course, all the characteristic elements of Wellner

heraldry: the dice, the elephant, the AWS logo and the three

elves, mentioned above, were widely used in the marks of August

Wellner & Sons factory. My accompanying article in

Member's Window of the same issue of ASCAS Newsletter

thoroughly discusses all known marks of silver-plated hollowware

used by this company. Here I would like to draw your attention

to the beautiful cutlery mark found on the Art Nouveau Wellner

ladle, issued in the beginning of XXth century.

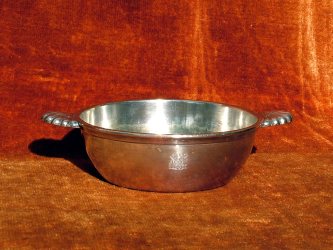

Wellner hollow ware items from my collection

The hollow ware

silver-plated products issued by the August Wellner & Sons

company are notable for their excellent long-lasting quality

which is due to the thickness of the silver layer and the

thorough respect of plating technology. Concluding the article,

I wish to present some remarkable items from my collection, made

about 110, 100, 90 and 80 year ago.

I am grateful to Dr. Albert A. Ruth for his invaluable help

in the translation of German sources and to Ms. Irene Horne for

her careful reading of my manuscript. My e-mail address is niko@phys.ucc.ie.

Any comments, questions or letters with additional information

are very welcome. However, please do not send any requests for

valuation and/or expertise, such letters will be ignored.

LITERATURE

[1] Reinhard W. Sänger, Das Deutsche Silber-Besteck,

Stuttgart, Arnoldsche, 1991, 1-286, (in German). English

translation of the title: German Silver Cutlery.

[2] Dedo von Kerssenbrock-Krosigk, Claudia Kanowski, Modern Art

of Metallwork. Berlin, Bröhan Museum, 2001, 1-598.

[3] Wikipedia, Die freie Enzyklopädie. "Ernst August Geitner".

http://de.wikipedia.org/wiki/Ernst_August_Geitner, 2011 (in

German).

[4] Glückauf! Zeitschrift des Erzgebirgsvereins, vol.45, No.3,

pp.43-66, 1925 (in German). English translation of the title:

Glückauf! Journal of Ore Mountains Association.

[5] Wikipedia, Die freie Enzyklopädie. "Christian Gottlieb

Wellner". http://de.wikipedia.org/wiki/Christian_Gottlieb_Wellner,

2011 (in German).

[6] Wikipedia, Die freie Enzyklopädie. "Carl August Wellner".

http://de.wikipedia.org/wiki/Carl_August_Wellner, 2011 (in

German).

[7] Dr. Dietrich von Nathusius, Deutsche Besteck-Industrie, Aue,

Auer Druck- und Verlagsgesellschaft M.B.H., 1924, 1-40 (in

German). English translation of the title: German Cutlery

Industry.

[8] Wikimedia Commons. "Wellner". http://commons.wikimedia.org/wiki/Wellner,

2009 (in German).

[9] Wikipedia, Die freie Enzyklopädie. "Peter Paul Gaedt".

http://de.wikipedia.org/wiki/Peter_Paul_Gaedt, 2011 (in German).

[10] Wikipedia, Die freie Enzyklopädie. "Wellner". http://de.wikipedia.org/wiki/Wellner,

2012 (in German).

[11] Wellner/ABS GmbH aus Schneeberg.

http://www.original-wellner.de/, 2012 (in German).

Dr. David N. Nikogosyan

- 2012 -

Marks of European Silver Plate: X. WELLNER, Germany

Marks of Wellner Metal Ware Factory Products (Aue in Saxony)

www.silvercollection.it |

This is a page of A Small Collection of

Antique Silver and Objects of vertu, a 1500 pages richly illustrated website offering all you need to know about

antique silver, sterling silver, silverplate, Sheffield plate, electroplate silver,

silverware, flatware, tea services and tea complements, marks and hallmarks, articles,

books, auction catalogs, famous silversmiths (Tiffany, Gorham, Jensen, Elkington),

history, oddities ...

HOME - SITE MAP - SILVER DICTIONARY - COOKIES CONSENT AND PRIVACY

OTHER ARTICLES ABOUT: ANTIQUE SILVER

SILVER PLATE

ENGLISH SILVER

FRENCH SILVER

|

|